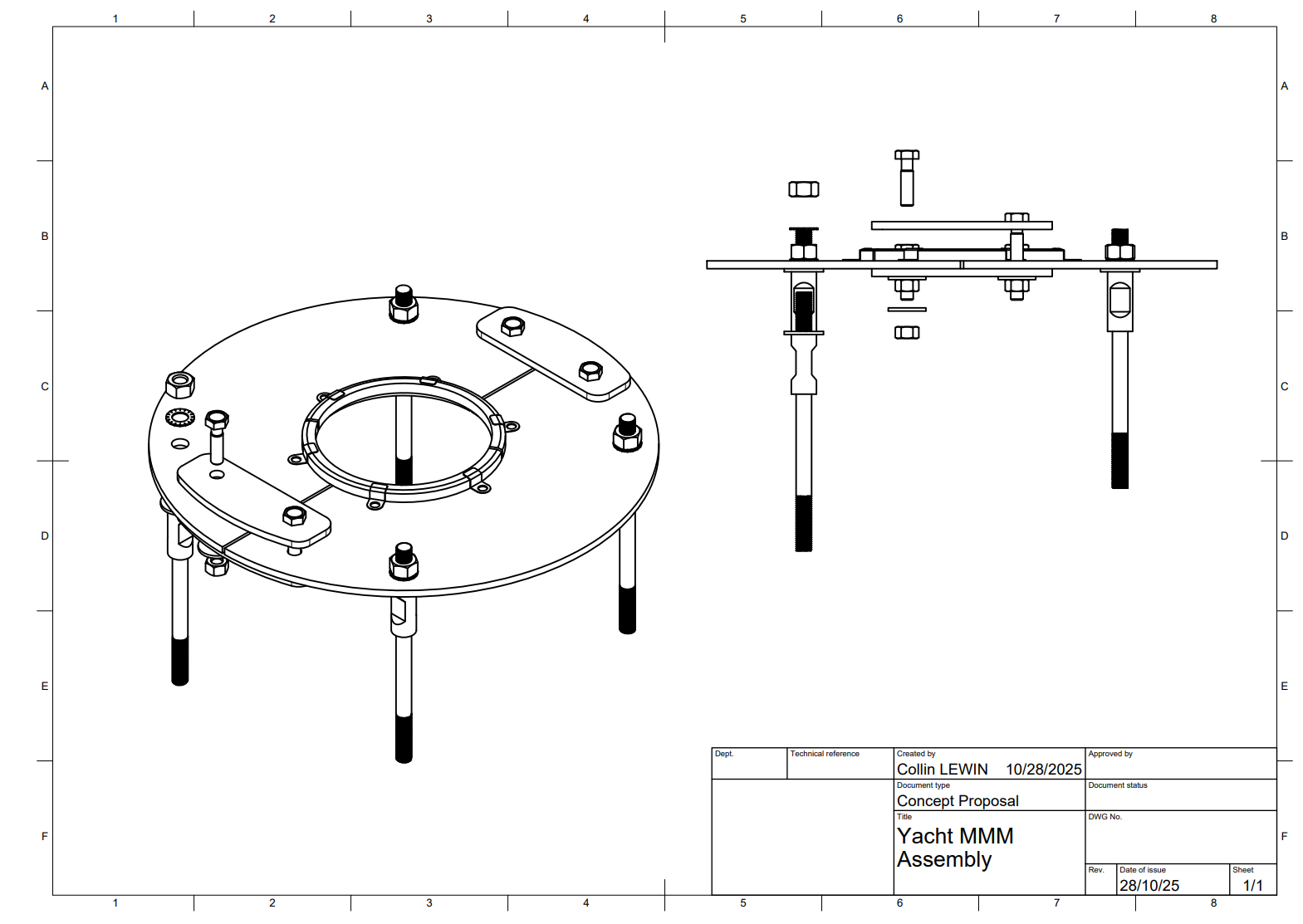

This project marked my first experience designing and fabricating a complex custom component for a client.

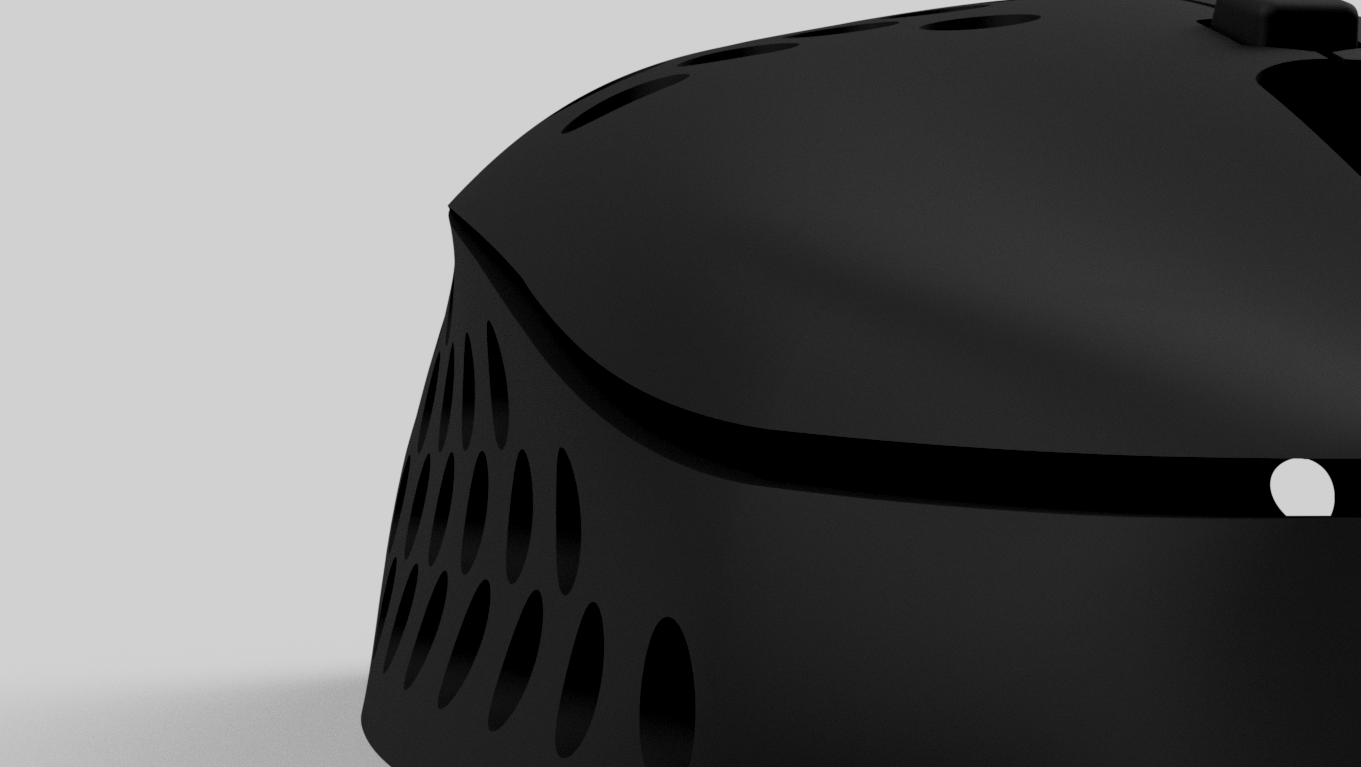

My father, who is currently involved in a motor yacht refit project, was working on a 650 kW electric motor that required a specialized solution. He needed a custom-designed support structure for a brush ring, which serves to ground the motor shaft and ensure proper electrical continuity.

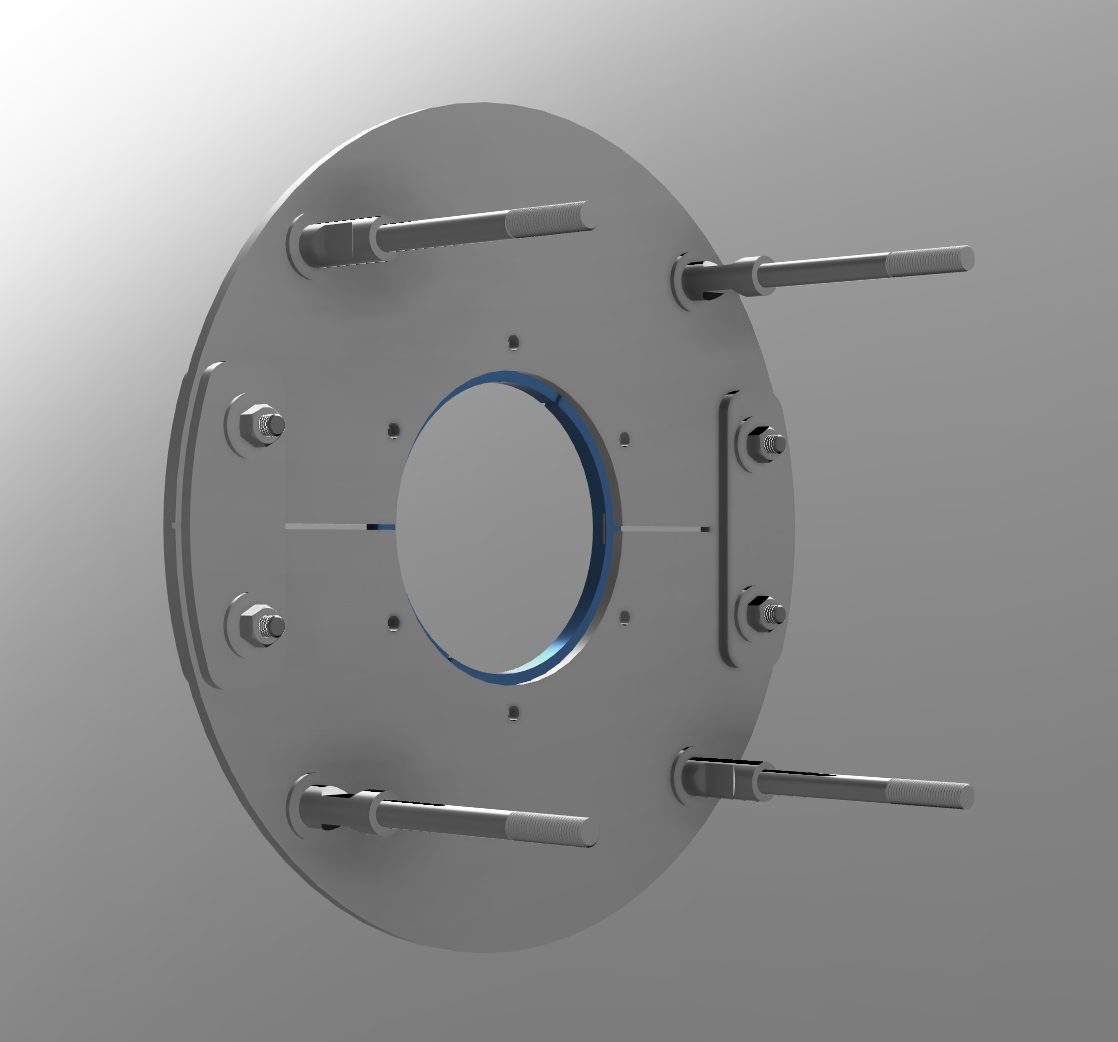

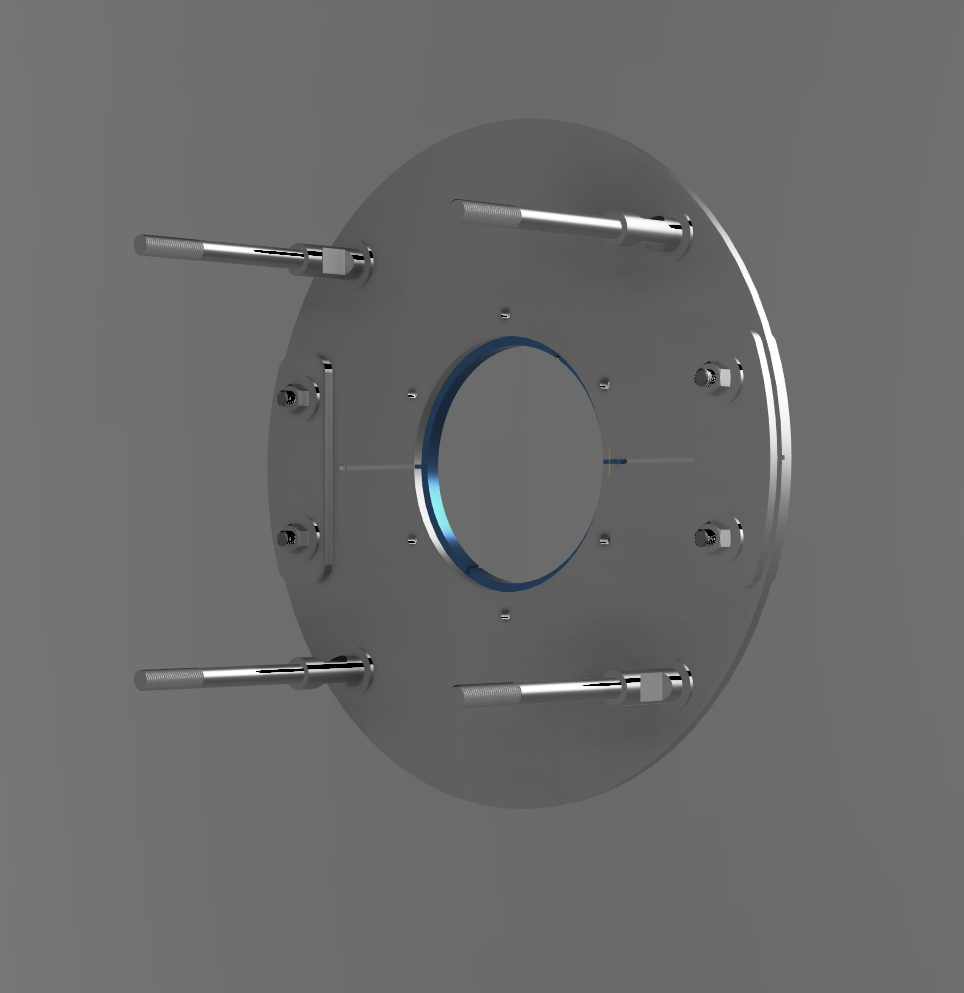

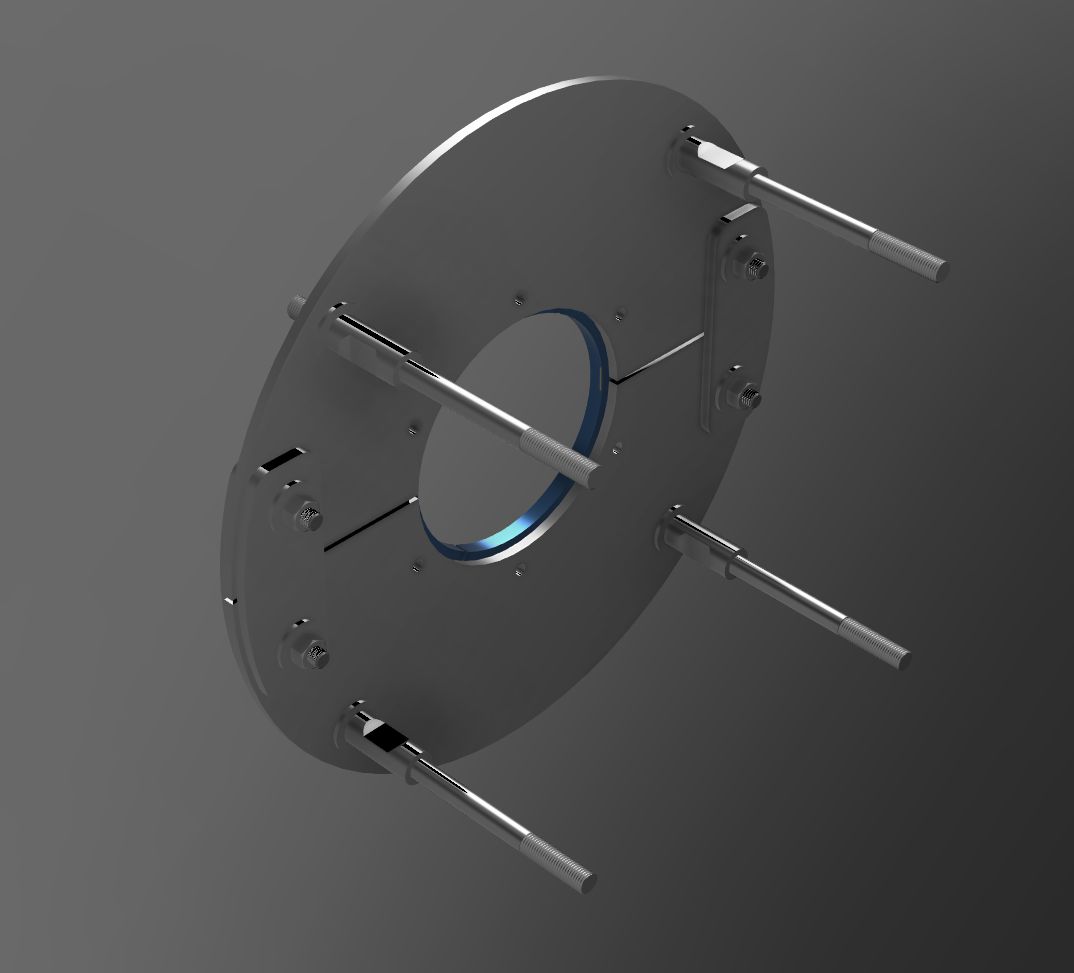

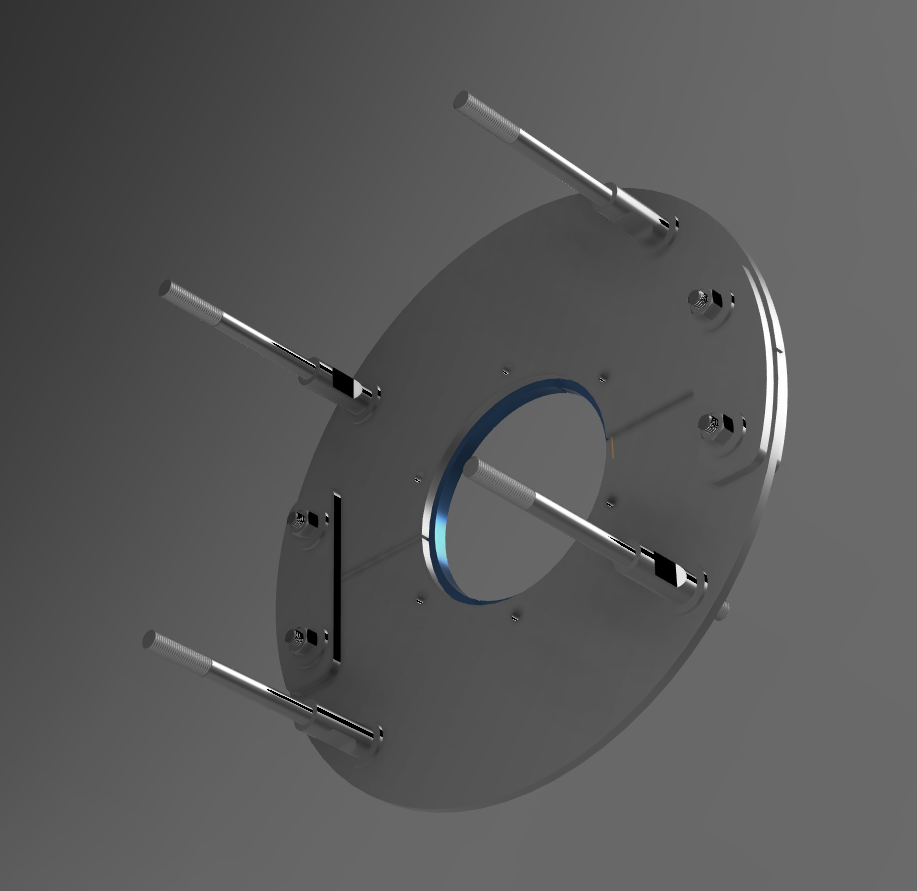

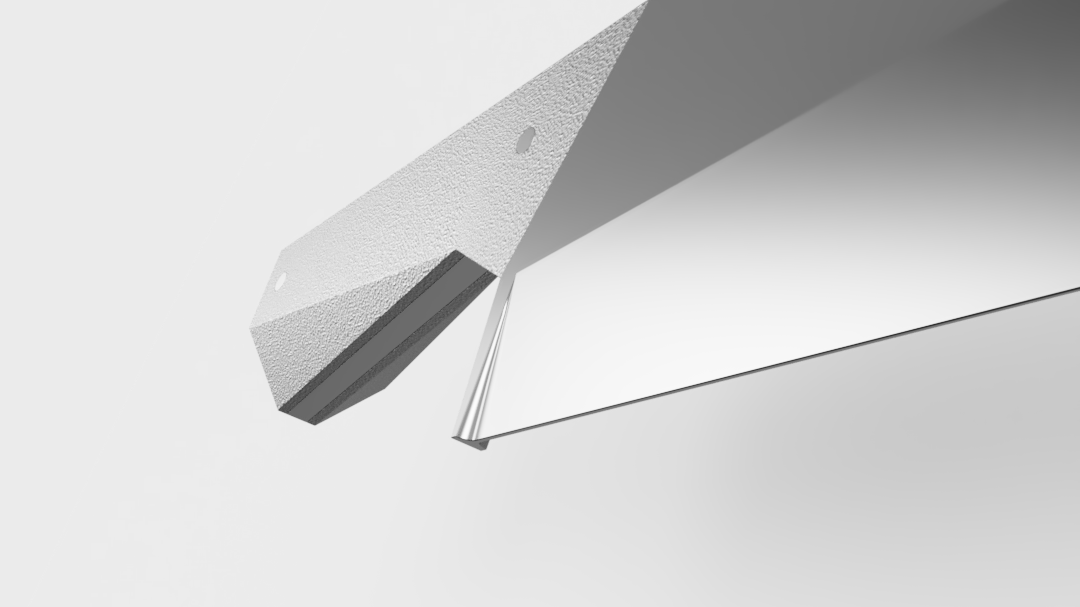

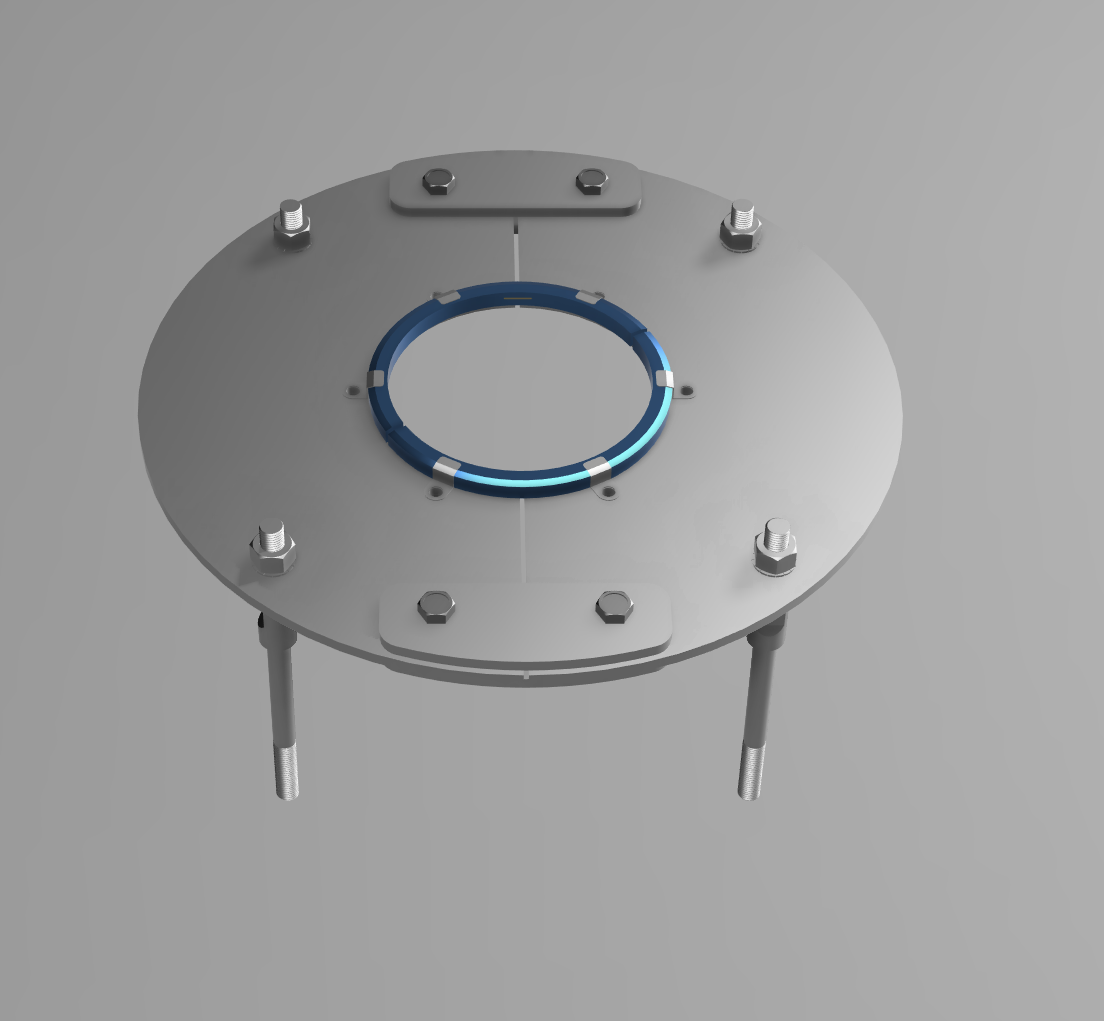

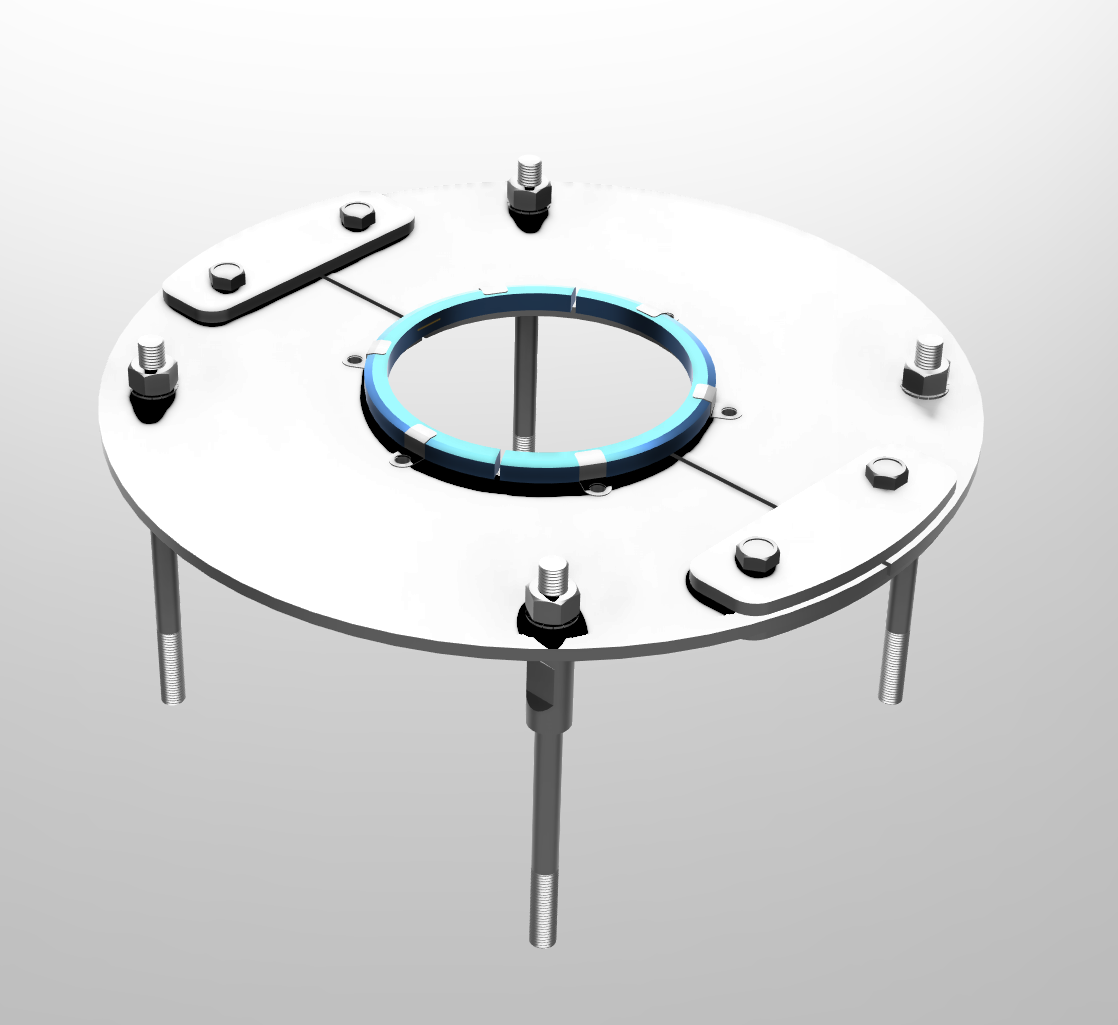

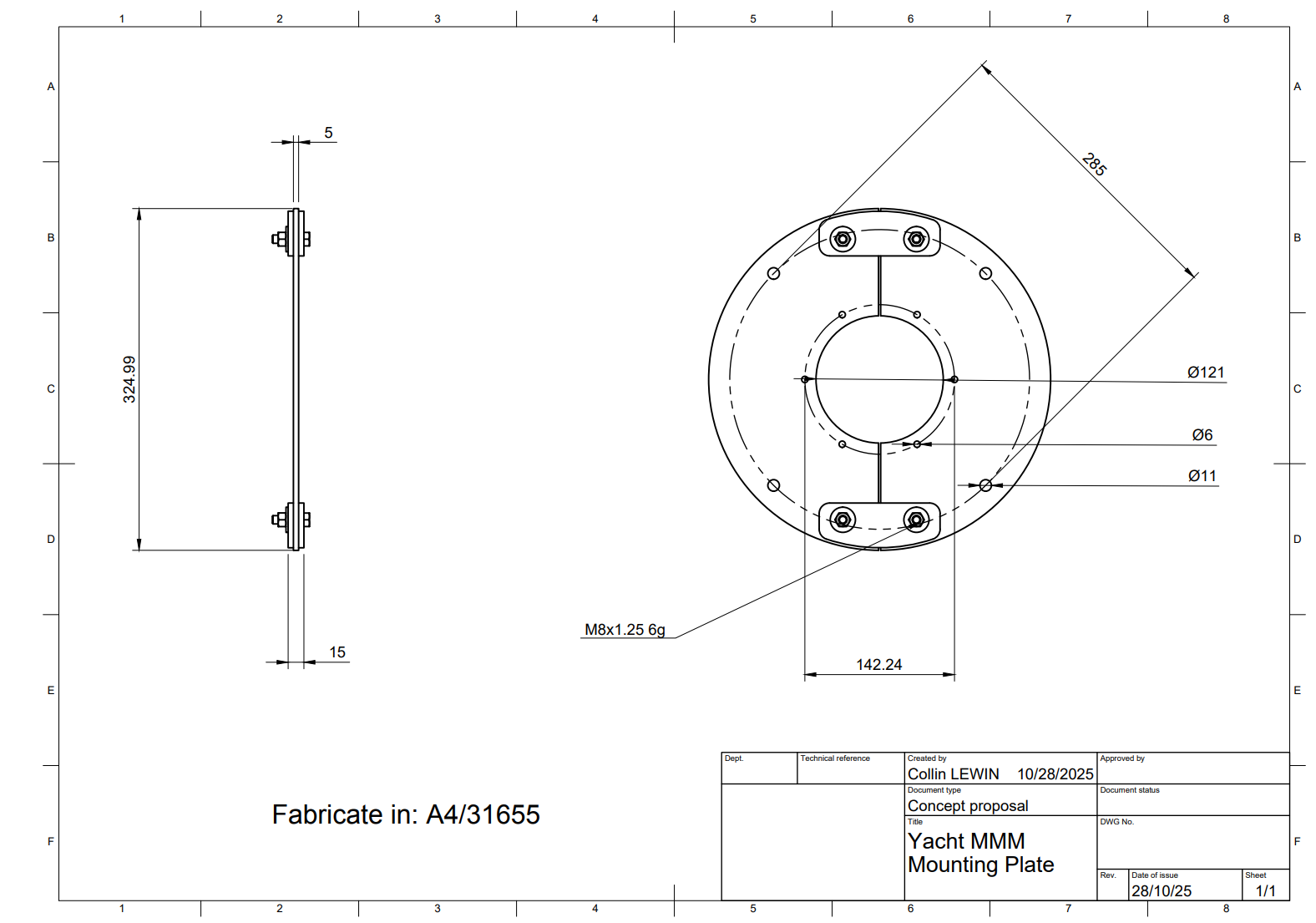

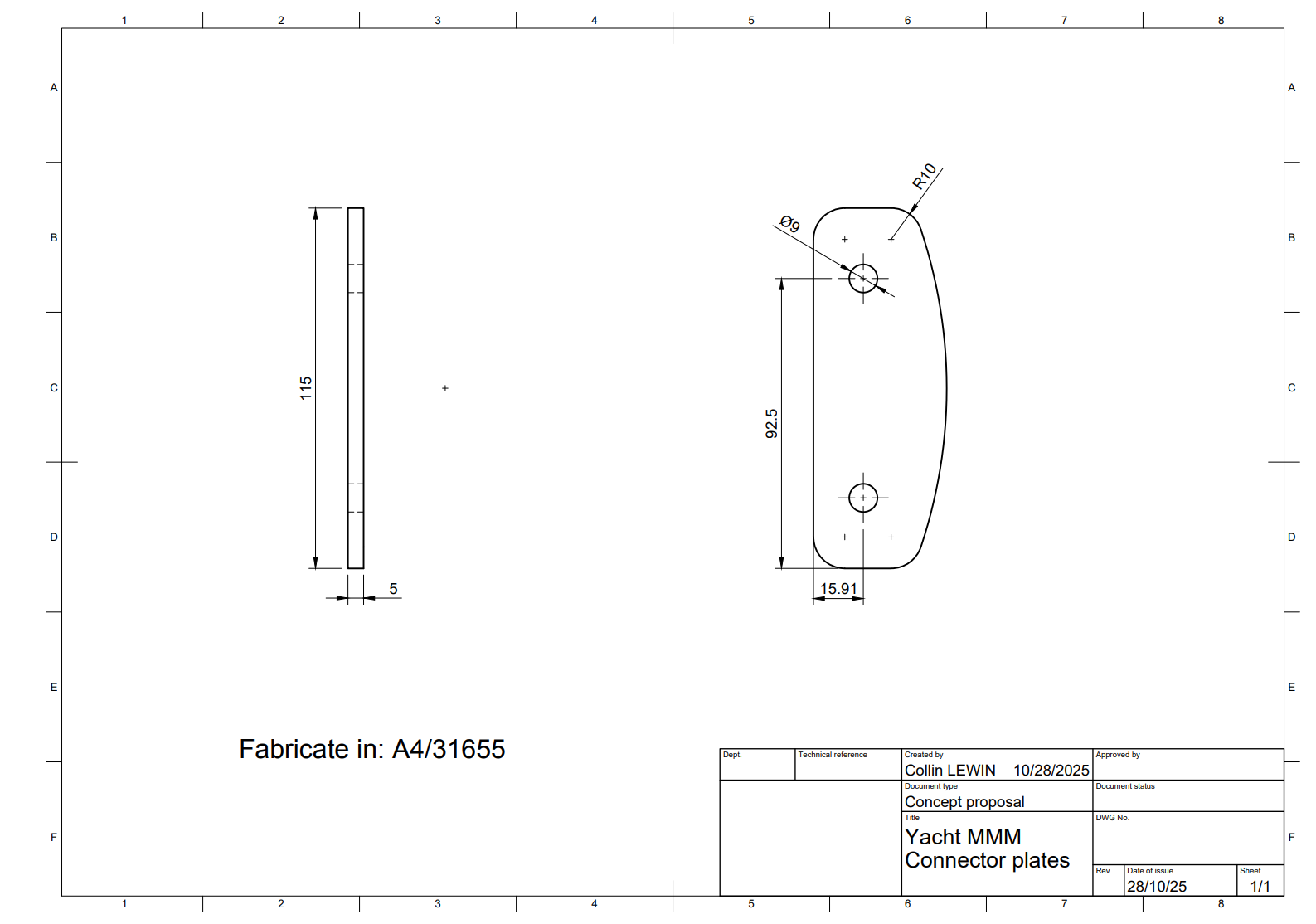

This build is composed of several precision-engineered components that work together to support and stabilize the brush ring assembly. It includes two semi-disc elements that provide the primary structural support for the brush ring, as well as 2×2 connector plates that securely fasten the support plates and ensure proper alignment of the overall structure.

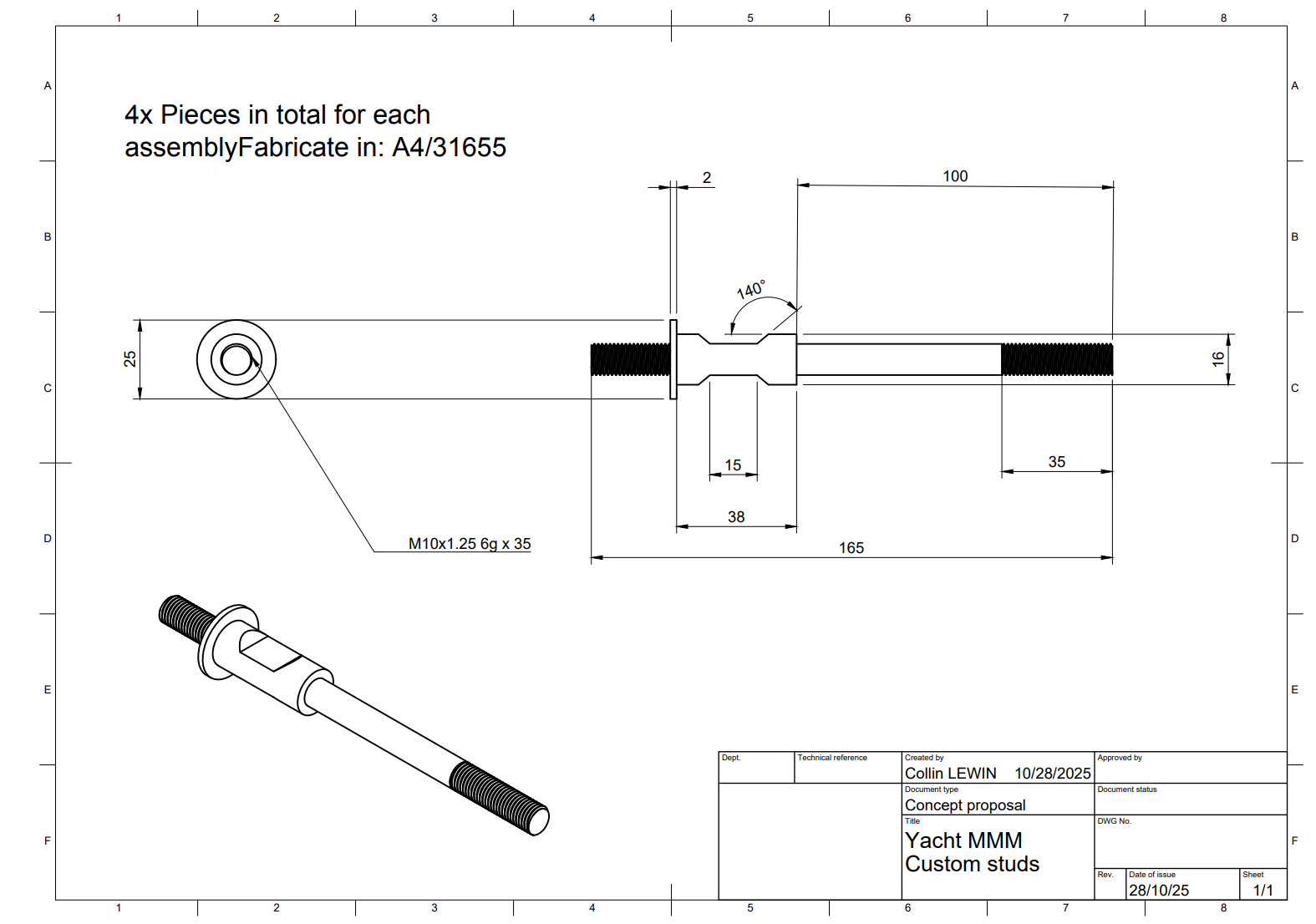

Additionally, four custom-designed studs were fabricated to mount onto the motor’s façade. These studs not only provide a stable connection point for the motor but also feature threaded ends that allow the brush ring to be easily attached or removed, facilitating maintenance and adjustments.